Guidance on plastic products banned from October 2022

This guidance is to support individuals, businesses and retailers who sell or manufacture any of the products banned from 1 October 2022.

From 1 October 2022 it is illegal to provide, sell or manufacture the following plastic products in Aotearoa New Zealand:

See the regulations: Waste Minimisation (Plastic and Related Products) Regulations 2022 (SL 2022/69) [New Zealand Legislation website].

Tranche 2 of the plastic phase outs came into force July 2023.

See future plastic phase outs for updates on Tranche 3.

Download the infographic [PDF, 2.7 MB]

Download the infographic [PDF, 2.7 MB]

Plastic is one of our greatest environmental challenges. Many single-use plastic products are used only once, not properly disposed of and end up littering our moana and whenua.

Hard-to-recycle packaging and products can cause contamination and interfere with our recycling systems.

Moving away from hard-to-recycle and single-use plastics will help:

A single-use plastic drink stirrer is any beverage stirrer made wholly or partly of plastic, including compostable and biodegradable plastic, designed to be used once or a limited number of times before being thrown away.

They are used by hospitality outlets that import them and are commonly sold by small retailers.

There are no exemptions to the ban on single-use plastic drink stirrers.

If the answer to both questions is yes, your single-use plastic drink stirrer may be included in the ban.

Instead of single-use plastic drink stirrers, you can manufacture or supply:

Reusable spoons (eg, metal) are a better alternative to single-use drink stirrers made from other materials (eg, wood) because they create less waste.

PFAS (including PFOA, PFOS etc.) are often used in single-use fibre packaging to provide resistance to oil compounds and water. PFAS are becoming a major concern as an ingredient in food contact materials as they can accumulate in the soil, plants, and consequently the food chain.

A single-use plastic cotton bud has a stem made wholly or partly of plastic with cotton wool (or synthetic fibre) wrapped around one or both ends, or has a non-plastic stem with synthetic fibre wrapped around one or both ends. They are designed to be used once or a limited number of times before being thrown away.

They are commonly used for makeup application/removal, removing nail polish, applying creams or lotions and cleaning ears.

The ban includes compostable and biodegradable plastic.

There are exemptions from the single-use plastic cotton bud ban for medical or scientific purposes.

This means they can still be manufactured and sold when the cotton buds are used:

If the answer to both questions is yes, your single-use plastic cotton bud may be included in the ban.

Instead of single-use plastic cotton buds you could manufacture or supply:

Pre-formed trays and containers that contain any PVC (plastic type 3) or polyvinylidene dichloride (PVdC) when they are used for products including:

A pre-formed tray or container is manufactured separately from the food it packages. If the PVC plastic is formed, filled with food and then mechanically sealed on the same line, it is not in the scope of this ban.

The regulations are not intended to ban PVC if they are used for other purposes not listed in this guidance and in the regulations. A ban on all PVC food and beverage packaging is expected under Tranche 3.

There are no exemptions to the ban on PVC pre-formed food trays and containers.

If the answer to both questions is yes, your PVC or PVdC packaging may be included in the ban.

Instead of PVC pre-formed trays and containers, you can manufacture or supply:

PET trays (plastic type 1) are a good alternative to PVC pre-formed trays. They can be recycled onshore into other PET products. You can find manufacturers at Plastics NZ. Alternatives that use recycled content help to reduce waste and emissions by keeping materials in use for as long as possible. PP trays (plastic type 5) can also be recycled in Aotearoa New Zealand.

Polystyrene (plastic type 6) used to package ready-to-eat food and beverages including:

Ready-to-eat means food and beverages supplied for immediate consumption such as food and beverages purchased for takeaway from a restaurant, café or stall, or cups provided at an office water cooler. It also includes food and beverages prepared for immediate dine-in eating (eg, sushi prepared at a café or restaurant).

The ban applies to any type of polystyrene (eg, expanded polystyrene and rigid polystyrene).

Examples of pre-formed polystyrene packaging for ready-to-eat foods:

Note that polystyrene drink lids (eg, coffee cup lids) are not in-scope of the polystyrene ban. The Ministry is currently looking at policy options for single-use cups and lids and we will consider PS drink lids through this work.

There are no exemptions to the ban on polystyrene takeaway packaging for food and beverages.

If the answer to both questions is yes, your polystyrene packaging may be included in the ban.

Instead of polystyrene packaging for ready-to-eat food and beverages, you can supply or encourage reusable packaging.

Businesses can encourage customers to bring their containers or you can sign up for a reusable container/packaging service that provides the type of packaging you need. Examples of reusable packaging services are AgainAgain and Reusabowl.

If reusable packaging is too challenging for your product/service, you can supply single-use packaging made from:

Single-use alternatives are available in Aotearoa New Zealand and online.

Food and beverage packaging made from expanded polystyrene (plastic type 6) and sold at retail. This includes pre-formed expanded polystyrene products (eg, food service ware) and form-fill-seal EPS packaging (eg, expanded polystyrene instant noodle cups).

Retail includes:

Under the Waste Minimisation Act 2008 'sold' also applies to products that are given away for free.

We heard through consultation that phasing out expanded polystyrene used to transport cold items such as medicines or seafood, and protective packaging for electronics and homeware items will be challenging.

Because of this expanded polystyrene used for these purposes is not included in the ban. The Ministry is working with sector experts to identify possible solutions and areas where alternatives could be used.

If the answer to both questions is yes, your product/packaging may be included in the ban.

Instead of using expanded polystyrene for food and beverage retail packaging, you can manufacture or supply:

For example, retailers can provide PP noodle cups instead of expanded polystyrene cups.

Plastic products with pro-degradant additives added to them (eg, oxo and photo degradable plastics). They are a subset of type 7 plastic.

These plastic items commonly (but not always) have pro-degradant additives:

Pro-degradant additives cause products to fragment into smaller plastic pieces (microplastics) which remain in the environment for a long time. Plastics with pro-degradant additives can’t be composted or recycled in New Zealand.

There are no exemptions to the ban on plastics with pro-degradant additives.

If the answer is yes the plastic product may be included in the ban.

Instead of products with pro-degradant additives, such as oxo and photo degradable plastics, you can supply or manufacture products made from:

Note that while biodegradable and compostable plastics are not in-scope of the ban on plastics with pro-degradant additives, they are included in the bans on single-use items (drink stirrers and cotton buds) which apply to all plastic resin codes 1-7. This is because drink stirrers and cotton buds are single-use items that are not always necessary and there are easily available non-plastic alternatives.

Biodegradable products leave only three by-products after breaking down in a specified timeframe. These are: water, carbon dioxide/methane, and biomass. To comply with the regulations you must be able to show your product breaks down into these three by-products.

You can achieve certification to show that your product composts, by using composting or anaerobic degradation standards.

To find out whether your product is biodegradable, you can use biodegradation tests which are specific components of the standards listed below. Note the list of standards is not exhaustive and is not an endorsement of any particular standard.

We encourage businesses to test whether their products are compostable or biodegradable in the type of environment the product is likely to end up in. For example if your product is certified to an anaerobic degradation standard, you should consider whether the product is likely to end up in a controlled environment (as opposed to landfills, which are exposed to a range of variables and are not always optimal for degradation).

Industrial compost certifications include:

Home compost certifications include:

Anaerobic degradation standards include:

See the Ministry position statement on compostable products for information on whether compostable packaging is a good solution for your product.

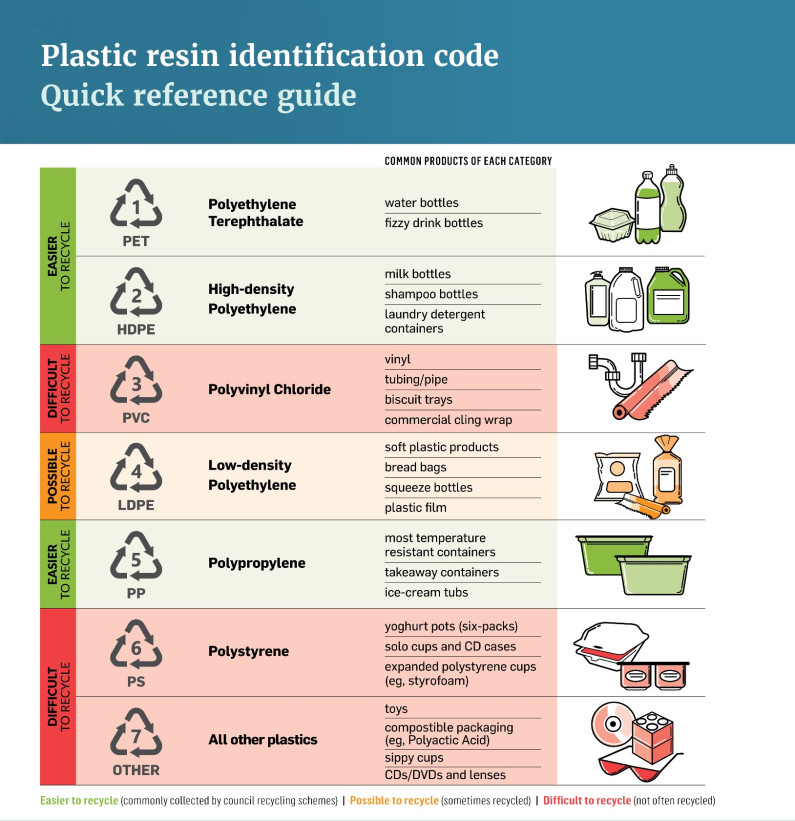

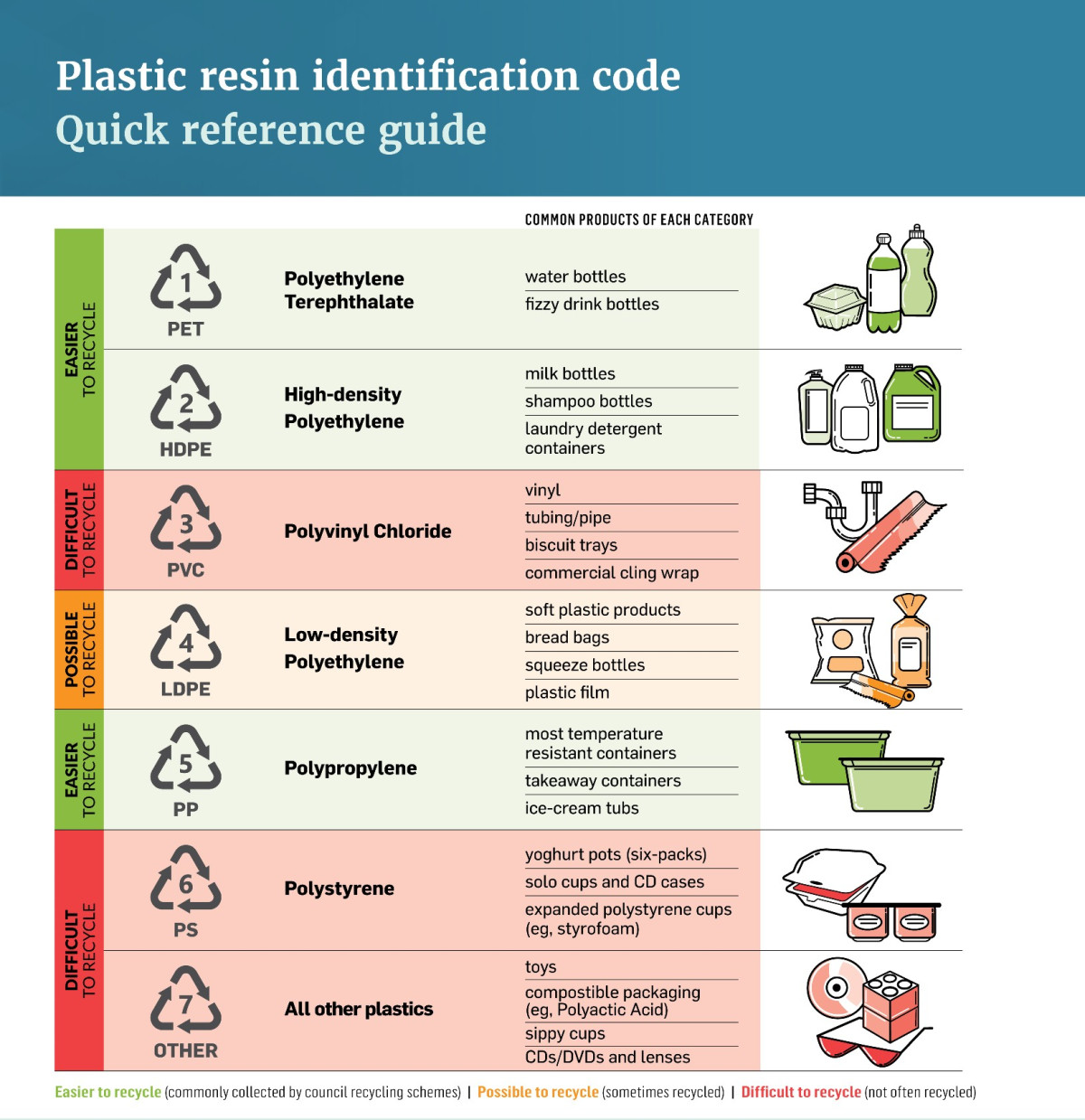

The plastic phase-outs are targeting hard-to-recycle plastics which are made from PVC (plastic type 3) and polystyrene (plastic type 6). These plastic types are challenging to recycle and have very limited recycling options available.

We are not phasing out plastic packaging made from plastic types 1, 2, 4 and 5 — unless they are captured by a single-use item ban such as cotton-buds or drink stirrers. Products made from plastic types 1, 2, 4 and 5 are available from packaging suppliers. These plastic types have some recycling options.

We are phasing out oxo and photo degradable plastics which are a small subset of plastic type 7. Other type 7 plastics are still available (eg, compostable and biodegradable plastics).

The illustration below shows the different types of plastic and how recyclable they are in Aotearoa New Zealand. Plastic types are usually identifiable by a small number inside an arrow triangle.

| Common products of each category | |||

| Easier to recycle | |||

| Plastic type 1 | Polyethylene Terephthalate (PET) |

|

|

| Plastic type 2 | High-density Polyethylene (HDPE) |

|

|

| Difficult to recycle | |||

| Plastic type 3 | Polyvinyl Chloride (PVC) |

|

|

| Possible to recycle | |||

| Plastic type 4 |

Low-density Polyethylene (LDPE) |

|

|

| Easier to recycle | |||

| Plastic type 5 | Polypropylene (PP) |

|

|

| Difficult to recycle | |||

| Plastic type 6 | Polystyrene (PS) |

|

|

| Plastic type 7 | All other plastics |

|

| Common products of each category | |||

| Easier to recycle | |||

| Plastic type 1 | Polyethylene Terephthalate (PET) |

|

|

| Plastic type 2 | High-density Polyethylene (HDPE) |

|

|

| Difficult to recycle | |||

| Plastic type 3 | Polyvinyl Chloride (PVC) |

|

|

| Possible to recycle | |||

| Plastic type 4 |

Low-density Polyethylene (LDPE) |

|

|

| Easier to recycle | |||

| Plastic type 5 | Polypropylene (PP) |

|

|

| Difficult to recycle | |||

| Plastic type 6 | Polystyrene (PS) |

|

|

| Plastic type 7 | All other plastics |

|

We realise the bans may mean some businesses have excess stock leftover following 1 October 2022.

The Ministry encourages voluntary compliance and expects that all businesses will be taking necessary steps toward ensuring they comply with the regulations.

We will use discretion when responding to any breaches of the regulations. We can respond to non-compliance in various ways ranging from education, providing verbal and written warnings through to prosecution.

In the first instance our preference is to take an educational approach and to offer advice to help businesses understand their responsibilities. The way we work is guided by our Compliance, monitoring and enforcement strategy.

The Ministry will take enforcement action where appropriate, particularly where systemic or ongoing non-compliance occurs. The Waste Minimisation Act allows for fines of up to $100,000 to be issued when parties deliberately contravene regulations under the Act. Any fines will be proportionate to the offence and all prosecution decisions are made subject to our Prosecutions policy and Enforcement decision making policy.

Fill out this online form for reporting suspected non-compliance.

The following questions are designed to help you make better decisions when choosing alternatives to a product that is banned from 1 October 2022.

Understanding how the product is made means you can choose a product that uses fewer resources and produces less greenhouse gas emissions.

Understanding where the product is made allows you to consider greenhouse gas emissions. Choosing products made in Aotearoa reduces greenhouse gas emissions from transport and helps to support the local economy.

Understanding what the product is made from means you can choose a product that is made with more easily reprocessed and/or more sustainable materials.

Choosing products that are reusable means that you can purchase less and save resources (eg, plastic drink stirrers can be replaced with metal stirrers such as spoons).

Understanding if the product is recyclable or not means that you can choose a product that can be reprocessed into another product rather than being sent to landfill.

Products that have recycled content are less resource-intensive to produce than products with no recycled content.

Understanding how the product performs for your purposes is important to deliver the best outcomes for you and your customers.

The Government is introducing new regulations to ban some hard-to-recycle and single-use plastic products being sold or manufactured in Aotearoa.

From 1 October 2022 the following products are not able to be sold or manufactured in Aotearoa:

There are exemptions for plastic cotton buds to ensure they can still be used for legitimate scientific and medical purposes.

Explain and show the alternative products you will be providing/stocking for example:

If you have questions contact the plastic phase-out team at plastics@mfe.govt.nz.

Guidance on plastic products banned from October 2022

February 2023

© Ministry for the Environment